Automotive Lifts: A Short(ish) History

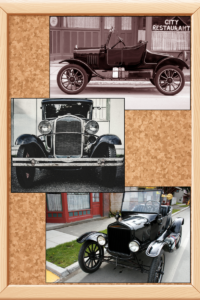

News of the first automobile hit the newspapers in July 1886. It was a three-wheeled motor car patented by Carl Benz of Mercedes-Benz fame. This new invention looked like a cross between a carriage pulled by horses and a bicycle. It bore a single seat and lightweight spoked wheels. It was an innovation, but it was also a luxury. The mass-produced Ford Model T didn’t hit the production floor until 1908. The Model T was a sturdier and somewhat more affordable option for families. Before long, most American families had a car. It makes sense that automobile maintenance would likewise experience a boom. Working on cars in those days meant climbing into a dirty pit or propping the car up with… creative solutions that weren’t always the safest. The garage pit is still in use today at oil change businesses and garages around the world. But in 1924, an innovation appeared. It revolutionized the way we maintain and store vehicles big and small. That innovation was automotive lifts.

In this article, we’ll discuss:

- How automotive hydraulic lifts work

- The history of automotive lifts

- The kinds of automotive lifts there are

- And how they have transformed since their start

We’ll also introduce SLETech, Inc., and our divisions. Want to learn all about automotive lifts? Keep reading.

Table of Contents

- Intro

- From Pascal’s Principle to Hydraulics Lifting Cars – How’d We Get Here?

- Automotive Lift Manufacturing Takes Off

- Types of Automotive Lifts

- How Automotive Lifts Have Evolved Over Time

- So Who Are We and Why Are We Writing About This?

From Pascal’s Principle to Hydraulics Lifting Cars – How’d We Get Here?

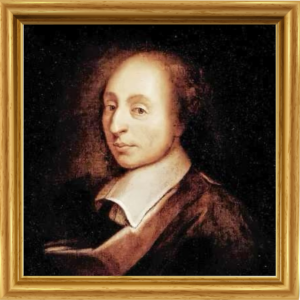

Scientists and mathematicians in the 17th to 19th centuries explored fluid dynamics. They learned how fluids move. What’s more, they quantified how machines can use fluids to move other things. We’re not going to get too specific about fluid dynamics. It’s important to note one thing, though. We’ve got to talk about Pascal’s Principle.

What’s that? The most fundamental observation leading to the modern uses of hydraulics.

Blaise Pascal was a French scientist and mathematician. He published his findings on the behavior of water and other fluids in 1663. Pascal’s Principle states the following:

- “Pressure is equal to the force divided by the area on which it acts.”

- (Source: Brittannica)

So… what does that mean in practice? Imagine a bottle of water ¾ full. If you squeeze the water bottle, the water will rise to the top of the bottle. If you squeeze hard enough, it might even pop the cap or rupture the plastic bottle. The force you use to squeeze the water transfers to the water and its container without losing any of its oomph. Scientists and inventors have used this principle to make great discoveries.

We use fluid hydraulics in many everyday settings. These include the shocks that hold your car’s trunk open and the tool used to boost up customers in the barber’s chair. That particular innovation inspired a man named Peter Lunati. In 1925, he patented the first vehicle lift. Today, hydraulics feature in many automotive and industrial settings. They lift everything from sprint cars to modular homes. Have you ever seen first responders use those super-strong “jaws” to cut open crashed vehicles and rescue trapped victims? Hydraulics power those, too!

Automotive Lifts Manufacturing Takes Off

While hydraulics science had its heyday in the 19th century, automotive lifts got their start in the 20th. Here’s a quick list of some of the most important happenings in automotive lift history:

- 1925: Peter Lunati creates the first car lift, which rotates to allow mechanics to navigate on and off the lift without reversing.

- 1945: Nine car lift manufacturers establish the Automotive Lift Institute to ensure automotive lifts are designed, built, installed, inspected, and used safely.

- 1946: Lee Hunter. Jr., establishes Hunter Engineering, a leading automotive equipment manufacturer, in St. Louis, Mo.

- 1947: Koni Vehicle Lifts begins production in the Netherlands

- 1985: Stertil and Koni combine and enter the vehicle lifts market as Stertil-Koni.

- 1992: Challenger Lifts is established in Louisville, Ky.; the company is the creator of the Versymmetric lift system, expanding service capabilities.

- 1996: Stertil-Koni produces first mobile column vehicle lift, transforming the automotive lift market.

- 2005: Stertil-Koni produces first Bluetooth wireless mobile column vehicle lift.

Types of Automotive Lifts

When you think of automotive lifts, you might think of two-post lifts lined up in car dealership bays or storage lifts in car enthusiasts’ garages. Actually, there’s a wide variety! Some are small enough to lift motorcycles or sprint cars. Meanwhile, some heavy duty lifts hoist dump trucks with ease. Let’s take a walk through some of the automotive lifts on the market, from smallest to largest.

Power Sport Lifts

Having a lift at your disposal can reduce backaches and increase your safety as you work on it. This is true whether you’re maintaining an all-terrain vehicle (ATV) for recreation, a utility terrain vehicle (UTV) for work, or a motorcycle. Power sport lifts can generally lift a capacity of 800 to 2,200 pounds, giving you confidence you can easily hoist your jet ski, motorcycle, or UTV.

Single-Post Lifts

Single-post lifts can be used as storage lifts or as portable lifts for temporary lifting of different types of vehicles, depending on your needs. For example, you might store a lawn mower on a single-post storage lift, or use a single-post mobile lift for car inspections in tight areas.

Two-Post Lifts

Two-post lifts consist of two columns, connected either by a floor plate or a bar at the top, and two lift arms on each column. They can be symmetrical or asymmetrical, based on the vehicle’s needs. Or, in the case of Challenger Versymmetric lifts, they can be convertible to allow one lift to hoist more kinds of vehicles.

Two-post lifts can generally handle 9,000 to 12,000 pounds.

Four-Post Lifts & Storage Lifts

These kinds of lifts are known somewhat interchangeably as four-post lifts or storage lifts. People use them to store a vehicle lifted in their air and one parked below. They can be used for just a few hours, such as in the case of valet parking, or for as long as you need. They’re a common solution used by car enthusiasts who want to make more room in their garage. They can typically hoist within 8,000 to 18,000 pounds.

Mobile Column Lifts

Unlike single-post lifts, mobile column lifts are intended to be used in conjunction with several others. They are positioned under the tires of a vehicle and lift simultaneously, whether they use a wired connection to each other or a Bluetooth connection.

The Stertil-Koni wireless mobile column lift is rated to lift 19,000 pounds, so a group of 4 or more can lift very heavy vehicles, from school buses to construction cranes. In fact, you can connect up to 32 of these powerful lifts!

Scissor Lifts

Scissor lifts are a kind of auto lift that can be built for vehicles of all sizes. Their crisscrossed arms sit flat so the vehicle can be driven onto the lift, then pneumatic or hydraulic systems open the arms to lift the vehicle in the air. You can find motorcycle scissor lifts, scissors for cars and trucks, on up to heavy duty scissor lifts strong enough for semi trucks.

Heavy-Duty Truck Lifts

Heavy-duty truck lifts are the bulldogs of the automotive lifting world, with enough power to safely and reliably lift everything from buses to fire engines and even train cars. They come in several varieties, including the aforementioned wireless mobile columns.

Other types of heavy-duty truck lifts include 2- and 4-post lifts, clear-floor vertical lifts, in-ground piston lifts, and even heavy-duty scissor lifts. While it’s clear that heavier vehicles require unique solutions, lift manufacturers aren’t afraid to rise to the occasion.

How Automotive Lifts Have Evolved Over Time

Many innovations have been integrated into automotive lift equipment over the years, making lifting vehicles easier, safer, and more efficient. Thanks in no small part to the Automotive Lift Institute, lifts today are made of high-quality materials and when maintained properly, safely serve auto shops for many years.

The lift is an innovation in itself, eliminating the need for mechanics to roll under cars on their backs or climb into dirty, poorly-ventilated pits. Asymmetrical lifts let cars sit farther away from the lift columns, more easily allowing the mechanic to access the car’s interior.

Companies with an eye on the future are making eco-friendly changes to their designs, like lifts that require less hydraulic fluid and have smaller footprints in the shop. Other innovations include LED displays to increase the ease of use of machinery and modular lift arms to allow greater capability. According to leaders in the hydraulic industry, AI is being used through smart sensors, advancements in analytics, and more to lower costs and emissions and increase efficiency.

So Who Are We and Why Are We Writing About Automotive Lifts?

SLE Technologies, Inc., is a full-line sales and service company serving the Midwest for nearly 50 years. We are the exclusive representative in Ohio, Kentucky, and Indiana, and portions of Wisconsin, Missouri, and Illinois, for the premier heavy-duty automotive lift manufacturer in the world, Stertil-Koni. We’ve won “Rookie of the Year” and “#2 Nationwide Distributor” awards from Stertil-Koni as well as the prestigious Aspire Program Award, acknowledging the company’s year-over-year growth.

In addition to our heavy-duty territories in Indiana, Missouri, Kentucky, Wisconsin, and Illinois, SLE in 2024 launched Freedom Shop Equipment, a direct-to-consumer eCommerce brand serving a nationwide audience.

We have humble beginnings and we’re proud of them, but with our years in the industry, we’ve learned a lot. We want to share our knowledge and connect with people who want real answers to their questions and problems.

So if you want to stay connected with us and learn about the automotive lift industry, there is one major way to keep your finger on the pulse. Subscribe to our blog and never miss an update!